XH-432-25-3多层共挤流延机:

一、产品特点:

多种聚合物熔体分别通过共挤模具汇集后,成为一种由多层不同聚合物熔体构成的薄膜熔体流,经冷却得到多层共挤薄膜或片材;

After various polymer melts are collected through co-extrusion die head, they form into a melt flow composed of multiple layersof different polymer melts, which is cooled to obtain multi-layerco-extruded films or sheets.

PLC系统程控一体联动,完成挤出、熔体计量、熔体压力监测、流延、压延、收卷或裁切等工艺;

The integrated linkage of PLC system program control to complete extrusion, melt metering, melt pressure monitoring, casting, calendering, winding or cutting and other processes.

进口熔体计量泵搭配压力传感器,熔体压力监测,保证熔体流量始终一致.

Theimported meltmetering pump is equipped with a pressure sensor to monitor the melt pressure, ensuring that the melt flow rate is always consistent.

二、技术参数:

型号 Model No. | XH-432-25 | XH-432-25-3 |

设备Name | 单层 Single layer | 三层共挤Slayers |

螺杆直径 Screw diameter | 25mm 或指定(or customized) | |

长径比L/D | 33:1 或指定(or customized) | |

螺杆转速Screw speed | 0-95rpm变频调速 | |

主电机功率Motor power | 4KW 或指定(or customized) | |

模唇宽度Die lip width | 300mm 或指定(or customized) | |

选配配置 Optional configuration | 熔体泵 3CC 或指定(3CC melt pump or customized) | |

液压换网器Manual or hydraulic screen changer | ||

压力传感器Pressure sensor | ||

放卷装置 Unwinding device | ||

压延机组 calendering part | 160 x 350mm x 2条 或指定 or customized | |

压延辗安装方式 Installation method of calender roller | 立式或平行 Vertical or parallel | |

收卷装置 Winding device | 摩擦收卷 Friction winding | |

体积(W x D x H) Volume | 2800 x 800 x 1650mm | 3500 x 1600 x2200mm |

重量(kg) Weight | 约750kg | 约1.2T |

电源 Power Supply | 3∮,AC380V | |

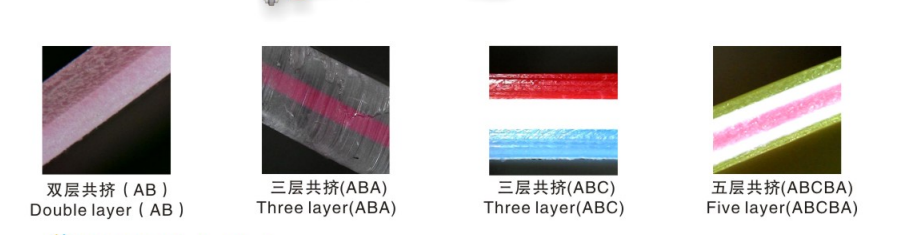

三、流延样品:

地址:广东省东莞市厚街镇溪宝路9号

电话:13302606117 网址:gdxihua888.com